Climate change/CO2 reduction: The best energy is that which is not used.

The world is talking about phasing out nuclear power, cutting back on fossil fuels, and increasing the use of renewable energy sources such as wind power and solar in order to halt the accelerating pace of climate change and thus the greatest catastrophe for mankind. This is not only good and right, but vital. But: The best energy is still the one that is not needed! Which of course also applies to small wastewater treatment plants. That is why ATB is now taking another decisive step in terms of climate protection, combined with a considerable extension of the service life of the plants!

With the APURIS® climate treatment plant, ATB has already created a small wastewater treatment plant that consumes only a fraction of the energy used by other technical small wastewater treatment plants, thus considerably protecting both our climate and the operator's wallet. With a reduction in energy consumption of up to 25%, the AQUAmax® small wastewater treatment plant is now following suit in terms of climate protection and CO2 reduction, thus earning the green "energy-optimized" award.

Energy optimization through threefold process modification in the new aControl®.

1. optimized aeration times

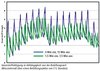

During the treatment phase within the cleaning process, the aeration times - for a plant size of 4 population equivalents - were previously 3 minutes each and the pause times 15 minutes. In numerous investigations we have now determined that the microorganisms responsible for the cleaning process accumulate or decompose significantly more pollutants with shorter aeration pulses and shorter pause times and thus the efficiency of the cleaning performance of the AQUAmax® is significantly increased. In practice, we have now been able to reduce the settings down to 1 minute aeration time and 7.5 minutes pause - without any loss of cleaning performance, but with a reduction of the aerator running time by 1/3 and an energy saving of up to 20%!

In addition to the enormous energy savings, another positive side effect is that the submersible motor aerators are subjected to considerably less stress, and the service life of the units is thus significantly extended.

2. sludge level function

Preclarifiers are filled with clear, clean water as standard after sludge removal. This means that the microorganisms no longer have any pollutants available for operational or structural metabolism - "normal" aeration is therefore not required at all at this stage. Our new "sludge level function" now reduces the aeration capacity after a sludge removal and thus saves more than 20% of the energy consumption within 4 weeks.

3. summer/winter time program

Based on our experience from more than 55,000 AQUAmax® plants installed worldwide in all climatic regions, as well as from thousands of plant maintenance visits annually, we know: In the months of December to February we need less aeration capacity in our latitudes - due to the higher oxygen saturation capacity of the water at lower temperatures. For this reason, we have equipped the plant control unit with a summer/winter time program that reduces the aeration time by 20% during the months of December to February - thus saving about 20% energy during this period.

Once again, our engineers have shown that with passion, perseverance and innovative strength, even an extremely successful small wastewater treatment plant such as the AQUAmax® can be further optimized or long established processes can be controlled even more efficiently: All' the described modifications to the AQUAmax® control system aControl® lead to energy savings of up to a fabulous 25%. Which also means: 25% less CO2, which affects our climate with harmful greenhouse gases. As we said: The best energy is the one that is not needed!