The PUROO ® small sewage treatment plants

Clean, safe, economic, efficient.

The PUROO ® small sewage treatment plants are particularly energy-saving, as our engineers have managed that the wastewater must be pumped out less often than with comparable small wastewater treatment plants. In addition, we have completely avoided noisy and unreliable magnetic valves. This makes the patented PUROO ® treatment process even safer and one of the most energy-saving systems ever. We work with energy-saving compressors. Therefore, there are no pumps or rotating electrical parts in the tank, i.e. in the wastewater. With the PUROO ® -COMPLETE option, you even have additional advantages: No fouling processes and even less odour annoyance.

The PUROO ® was even awarded the GreenTec-Award!

Of course, all PUROO ® sewage treatment plants also have all necessary approvals according to DIN-EN 12566-3 and have the DiBt approval.

This page is divided into the following topics. Click on the link to get there directly.

We will be pleased to offer you further sizes on request. Talk to our experts:

The PUROO ® SBR small sewage treatment plant also handles extreme wastewater loads.

The SBR sewage treatment plant PUROO ® is certainly the best small sewage treatment plant we have ever developed. Not only does PUROO ® work without pumps and fragile electric magnetic valves, it is also particularly robust.

Whether 200% overload, a strong underload of only 25% or wastewater inflow only on weekends: PUROO ® proves every day that a safe wastewater treatment is possible, even in case of strong load fluctuations.

Please also read our short report of the PIA (Prüfinstitut für Abwassertechnik, Aachen).

The idea for the PUROO ® small wastewater treatment plant

„Small sewage treatment plants are too complicated!“

In recent years, small sewage treatment plants have become more and more complicated. Many developments in the industry have only taken place because they were technically possible - but not because they were required by the customer.

The controls have been given more and more functions. There are even more sensors that can fail or cause malfunctions. A standard SBR small wastewater treatment plant usually still has 4 unreliable, loud magnetic valves or stepper motors. Some companies even offer to equip the small sewage treatment plant with an Internet connection to monitor it.

The result is that the operation, maintenance and repair of the plants have become increasingly complicated in recent years.

With the PUROO ® small sewage treatment plant by ATB WATER, we have found a solution to make small sewage treatment plants simple and safe again...

The technology - "This is how PUROO ® works.“

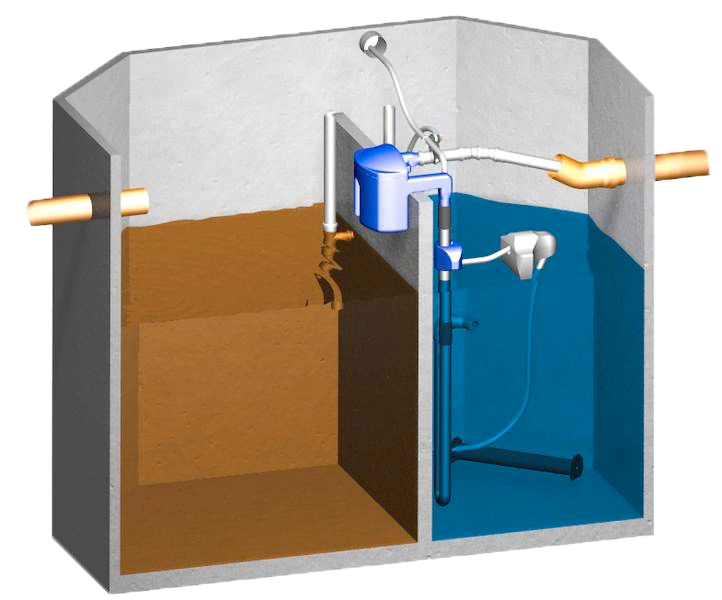

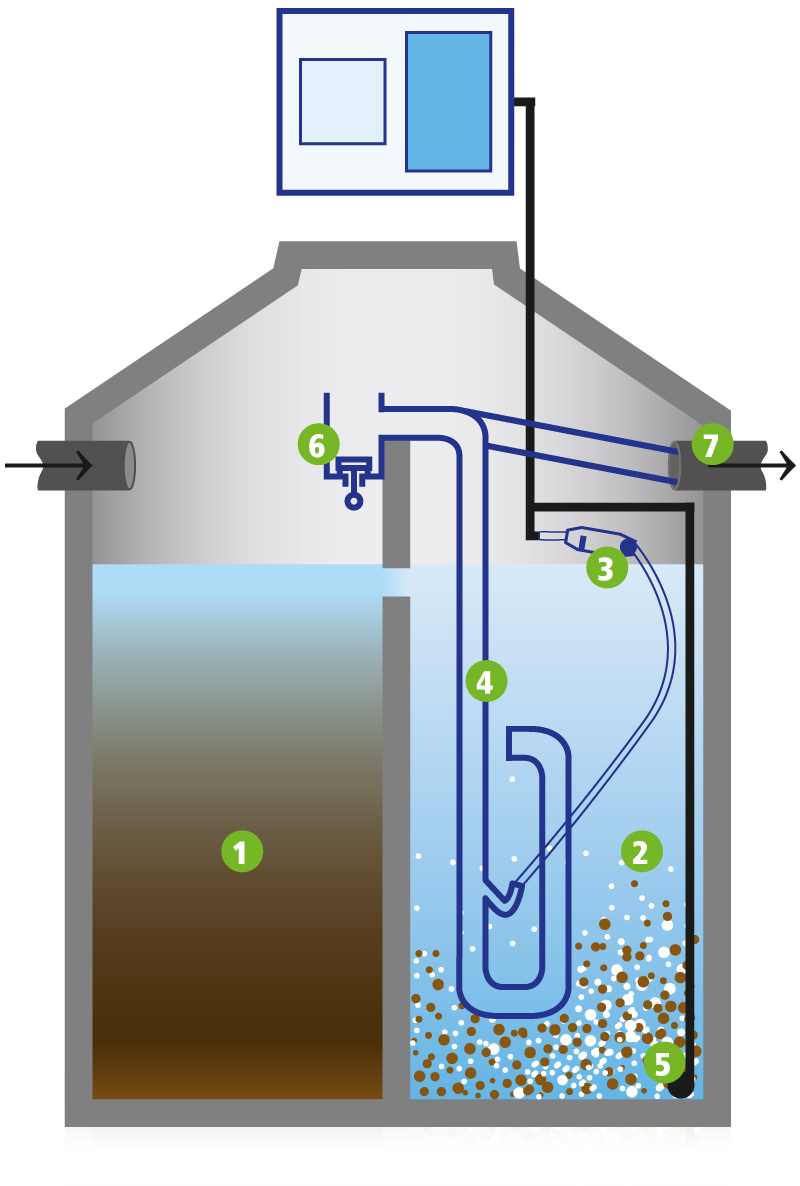

The untreated water flows via the pre-treatment (1) into the SBR tank (2).

In the SBR tank, intermittent aeration takes place until the mechanical ball-type float (3) activates the air lift (4) due to the higher water level. This activation leads to sludge recirculation in several short pump strokes.

This is followed by the settling phase. This allows the sludge to sink in the SBR tank.

The air lift is activated again and it now pumps the treated water out of the system (7).

A valve (6) integrated into the outlet distinguishes between short pump impulses(= excess sludge discharge) and long pumping operations (= clear water discharge).

At minimum water level, the air flow is switched back from the air lift to the pipe aerator (5). - The process starts again. The cycle is therefore not time-dependent but water level-dependent.

PUROO ® Complete

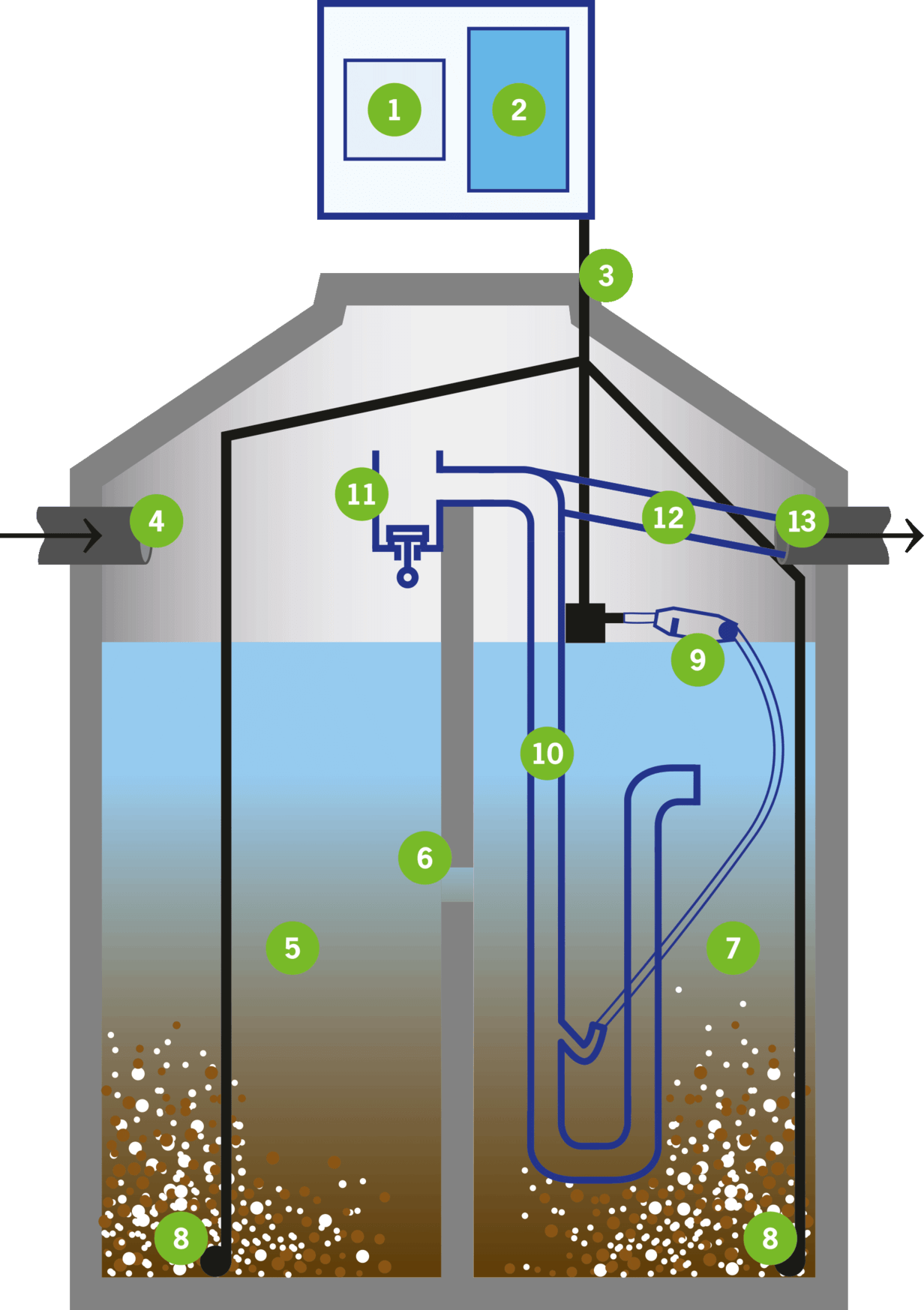

On the basis of our proven PUROO ® small sewage treatment plant, we have succeeded in developing an even more efficient plant. Like the PUROO ® plant, the PUROO ® Complete plant also works according to the activated sludge principle using the buffering process (SBR plant); the pollutants from the wastewater are absorbed by floating microorganisms (activated sludge) and converted into biomass.

The cleaning cycle is controlled by the water level, i.e. according to the real amount of wastewater.

With the PUROO ® Complete plant, aeration takes place not only in the aeration tank but also in the primary pre-treatment - this offers several advantages at the same time:

The added oxygen mineralizes the sewage sludge by decomposing carbon compounds; the sludge volume is reduced and sludge removal is required later than in plants without aerated pre-treatment.

The formation of fouling gases and acids is also prevented by the oxygen supplied; this virtually eliminates odour nuisance and concrete corrosion.

PUROO ®− The characteristics

„PUROO ® is easy.“

- One air lift only - less parts to install.

- Only one air hose - The connection between the control/blower and the system is easier.

- No magnetic valve, but a robust ball-type float, specially developed by ATB, controls the air flow directly, without electrical energy: purely by physics.

- Simple operation of the control, as the system has only a few functions.

- The sampling option is already integrated.

„PUROO ® is economic.“

PUROO ® saves energy. The water is only pumped once. Conventional SBR treatment plants pump the water twice.

Because the water is pumped once, the blower has to work less than in conventional SBR sewage treatment plants; this increases the service life of the blower.

Electricity consumption is only around 30 kWh per PE per year.

Maintenance costs are low as no magnetic valves or pumps are used.

An example calculation:

With an electricity price of 0.30 €/kWh, a fixed-bed or mooving-bed small wastewater treatment plant for 4 PE (population equivalent) consumes a total of 150 kWh per inhabitant & year and thus causes costs of 180 € per year. If you operate a PUROO ® small wastewater treatment plant instead, you will save € 144 per year, i.e. € 1,440 in 10 years, not including expected electricity price increases.

„PUROO ® is clean.“

Whether with heavy underload or with inflow peaks: PUROO ® simply adapts to the situation.

The primary sedimentation and the SBR chamber are connected to each other. The resulting larger buffer ensures better cleaning performance with fluctuating loads. The retention time of the wastewater is considerably longer.

We always use at least 80 Watt blowers to ensure sufficient safety and extend the service life. - PUROO ® therefore always has sufficient power reserves.

PUROO ® safely complies with the strict French limits for filterable substances (AFS) of less than 30 mg/l.

The efficiency in regard to BOD5 is 97.9 % and in regard to COD 95.1 % (according to EN 12566-3, PIA, Aachen).

„PUROO ® is safe.“

No fault-sensitive magnetic valves.

No pumps in wastewater.

PUROO ® works according to the SBR process.

For more than 12 years, this has been the most commonly built system for small sewage treatment plants. Since PUROO ® works according to the real wastewater volume, even surprising inflow fluctuations are safely cleaned.

In addition to testing according to EN 12566-3, PUROO ® has also undergone additional overload and underload situations on an approved test field.

PUROO ® is delivered with the proven and matured control based on the APURIS ®.

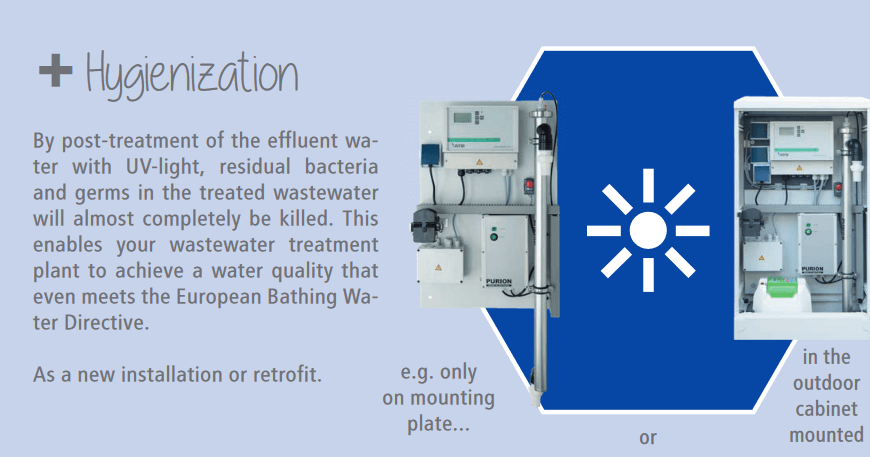

The ATB Modular System Plus+

Individual expansion options for your wastewater treatment plant. Combine existing or new wastewater treatment systems PUROO ® from 1-16 p.e. or AQUAMAX ® from 1-75 p.e. with hygienization, phosphate precipitation and/or remote data transmission and treat your wastewater to the maximum purification level. Almost all combinations of advanced wastewater treatment are possible with our systems in the modular system PLUS+.