Rental equipment from ATB WATER - the flexible option for wastewater treatment

Why renting equipment in the field of wastewater treatment is often more useful than buying it

In biological wastewater treatment there are always events and tasks where the use of rental equipment is a short-term and effective solution. Why ATB WATER's rental equipment offers the optimal solution for your application, what advantages it gives you and what aspects you should consider when making your decision:

► INTERIM SOLUTIONS

When converting existing plants, in many cases existing basins (e.g. sludge storage tanks or secondary clarifiers) are only used during the construction phase to bridge and maintain wastewater treatment. After completion of the new plant, the aeration equipment is removed from the temporarily used basins and returned with little effort.

► TEST OPERATION

When influent conditions vary greatly, are undefined, or only partial biodegradation is to occur, it is usually not possible to accurately size a plant. By a test operation with the help of ATB rental aerators, our customers can individually and cost-effectively check whether the planned technology meets their wishes and requirements.

► SEASONAL HIGH-LOAD PHASES

High water temperatures in summer or pronounced seasonal high loads (tourism, confectionery industry, etc.) can lead to a temporary need for additional aeration capacity. The most economical alternative to cover these peak loads is often to use our rental aerators instead of a costly and maintenance-intensive permanent expansion of the aeration system to the short-term maximum load.

► FINANCING

Rental units from ATB are an elegant solution to relieve the investment budget and can also be an interesting alternative to the purchase of aerators from a tax point of view.

Simply contact our sales team and receive your individual offer after detailed technical consultation. If there is no suitable rental unit available in our stock, we will of course also produce special units for your requirements. Should you decide to purchase the rental unit for permanent wastewater treatment, you will be credited with part of the rental fee paid up to the time of the purchase decision.

We are looking forward to your project! Click here to go directly to the availability of our rental units.

You are also welcome to take a look at our flip page catalog.

Our references

Municipal wastewater treatment plant with 3,900 P.E.

At a municipal wastewater treatment plant with 3,900 P.E. in Lower Saxony, the membrane pressure aeration of the activated sludge was to be completely replaced at the end of its lifecycle. The energy, maintenance and investment costs of different systems were compared.

The lowest annual costs came up for two floating ATB surface aerators of type HSA with 11 kW each. As the conversion of the system was associated with considerable costs, the customer first wanted to verify the calculated values in practice and therefore opted for the hire-purchase option. After successful trial operation over a period of several months, the devices were purchased with proportionate crediting of the lease.

Leachate pretreatment at a large landfill site

A leachate storage tank with 20,000 m3 on a large landfill in North Rhine-Westphalia caused problems for the landfill operator. Anaerobic degradation processes regularly led to strong acidification of the stored leachate in connection with very strong odour nuisance in a neighbouring recreation area.

After comparing different aeration systems, the operator decided to install a 55 kW HSA surface aerator for test purposes. The effect of the rented aerator on COD degradation and odour prevention was observed over several months. The test was judged successful and the aerator was purchased for permanent operation.

Rainwater treatment on a biogas plant

The transport routes on biogas plants are heavily contaminated with organic material due to the transport and storage of silage. These deposits are flushed out during rain events and in many cases mix with the silage leachate, which is difficult to manage separately. This highly polluted rainwater is collected in most biogas plants in storage tanks and then spread agriculturally.

The operator of a biogas plant in Schleswig-Holstein had set himself the goal of reducing the organic load and odour pollution during agricultural utilisation as much as possible by aerating the collection tank. Two floating surface aerators with 5.5 kW each were installed as rental units in the existing collection tank. During the test period of 6 months, the desired targets were achieved from the operator's point of view and the aerators were taken over into the ownership of the biogas plant.

Rainwater treatment on a biogas plant

On a biogas plant in the northern part of Schleswig-Holstein, the accumulating surface water is collected in a concrete basin and spread on the surrounding fields for recycling. The high nutrient and COD concentrations caused by contaminants washing off onto traffic routes led to the collected water already becoming highly acidic in the storage basin and to a strong development of odors. This led to complaints from residents and the application had to be carried out very widely and remotely.

Over a period of six months, an 18.5 kW submersible aerator was operated as a test unit to aerate the storage basin. Not only was a significant reduction in the organic load achieved, but above all acidification and odor pollution were completely eliminated and the surface water could now be discharged close to the plant without any complaints. After successful test operation, the operator of the biogas plant purchased the aeration system and put it into permanent operation.

Availability of our rental equipment

| Type | Model | Description | Status | Request |

| HSA | HSA-550 | Floating surface aerator with 55 kW | in maintenance | Request |

| HSA | HSA-450 | Floating surface aerator with 45 kW | rented | Request |

| HSA | HSA-450 | Floating surface aerator with 45 kW | reserved | Request |

| HSA | HSA-300 | Floating surface aerator with 30 kW | rented | Request |

| HSA | HSA-220 | Floating surface aerator with 22 kW | available | Request |

| HSA | HSA-220 | Floating surface aerator with 22 kW | available | Request |

| HSA | HSA-220 | Floating surface aerator with 22 kW | rented | Request |

| HSA | HSA-220 | Floating surface aerator with 22 kW | rented | Request |

| HSA | HSA-220 | Floating surface aerator with 22 kW | rented | Request |

| HSA | HSA-110 | Floating surface aerator with 11 kW | rented | Request |

| HSA | HSA-075 | Floating surface aerator with 7,5 kW | in maintenance | Request |

| HSA | HSA-075 | Floating surface aerator with 7,5 kW | rented | Request |

| HSA | HSA-030 | Floating surface aerator with 3 kW | rented | Request |

| HSM | HSM-110 | Floating mixer with 11 kW | reserved | Request |

| HSM | HSM-055 | Floating mixer with 5,5 kW | in maintenance | Request |

| HSM | HSM-055 | Floating mixer with 5,5 kW | rented | Request |

| HSM | HSM-030 | Floating mixer with 3 kW | reserved | Request |

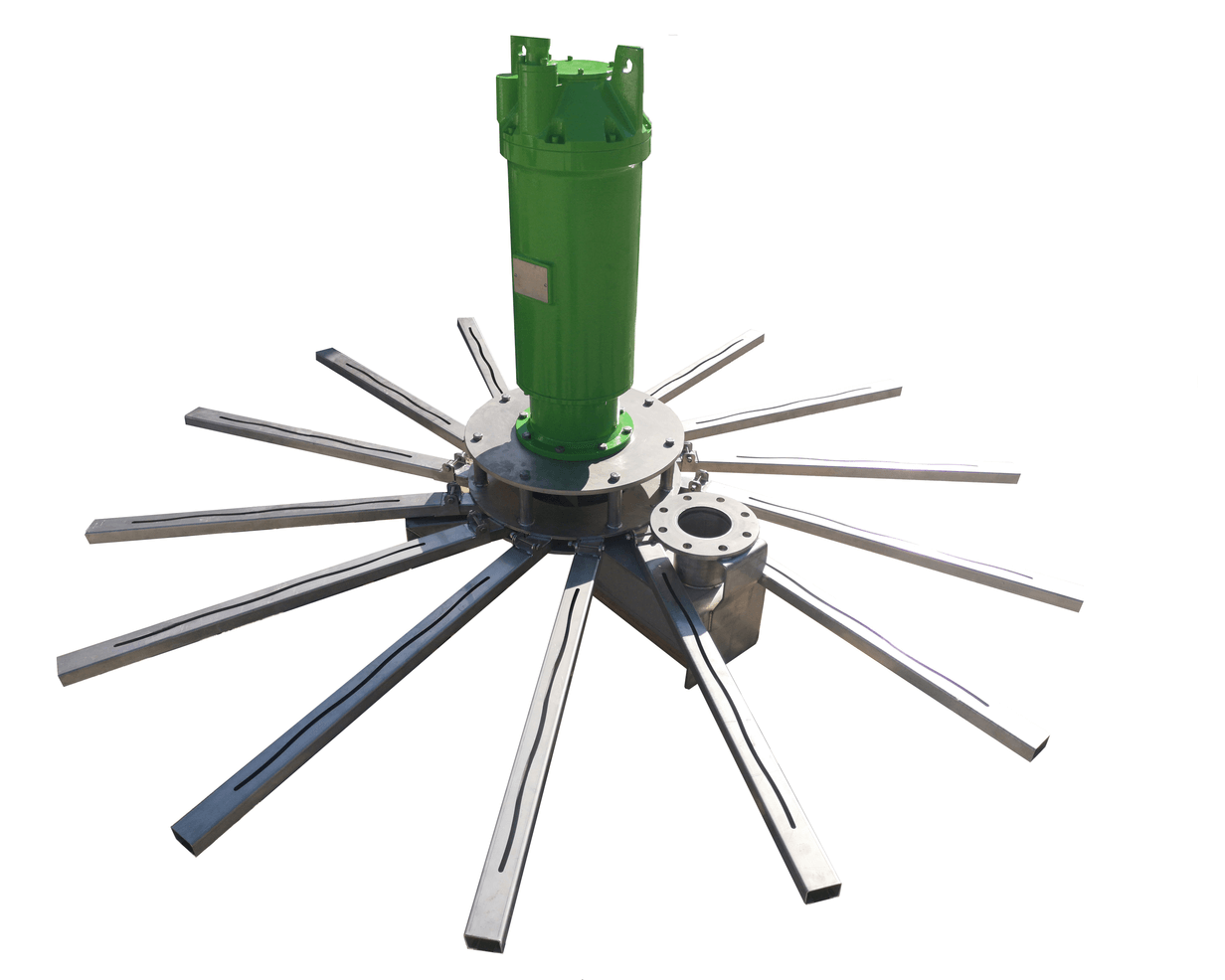

| HBA | HBA-220 | Submersible aerator with 22 kW | in maintenance | Request |

| HBA | HBA-150 | Submersible aerator with 15 kW | in maintenance | Request |

| HBA | HBA-150 | Submersible aerator with 15 kW | rented | Request |

| HBA | HBA-055 | Submersible aerator with 5,5 kW | rented | Request |

| HBA | HBA-055 | Submersible aerator with 5,5 kW | reserved | Request |

| HBA | HBA-015 | Submersible aerator with 1,5 kW | reserved | Request |